Wires

Shop Wires NowWires You Can Depend On

Our wires are manufactured in the U.S. using American raw materials and undergo a rigorous 28-point inspection to ensure the highest quality and performance.

We stand behind our products and customers with the Pain-Free Guarantee.

G4™ Nickel Titanium

Our G4™ Nickel Titanium is made from a proprietary formula developed through rigorous scientific research and testing and over 40 years of expertise. Formulated to perform ideally at body temperature, these wires produce lower initial load forces and increased residual forces as full-shape recovery progresses.

- Get a known, consistent and repeatable force every time.

- Active to the end, it moves teeth farther and faster.

M5™ Thermal Copper Nickel Titanium

Softer to the feel and easy to maneuver at room temp, these unique wires recover their ideal shape and desired force once in the mouth. Developed from a proprietary formula and rigorous testing, M5 Thermal Copper wires incorporate temperature transformation completed by 35°C for predictable tooth-moving forces and easier engagement.

- Gentler loading forces allow for easier engagement.

- Proprietary polishing process creates a smoother surface finish and improved sliding mechanics.

S3™ Stainless Steel

G&H stainless steel archwires are made from medical-grade stainless steel and continuously tested to ensure quality, precision and performance. We’ve reduced our manufacturing steps to ensure you get wires of the highest possible integrity and strength.

- Optimized manufacturing process allows you to add multiple step bends without breaking the wire.

- Proprietary polishing process creates smoother wires with enhanced sliding mechanics.

XR1™ Heat Treated Stainless Steel

Uniquely treated and stress-relieved to improve strength, resiliency and mechanics, these wires provide the extra force needed to get the movement you want. Formed using state-of-the-art equipment, XR1™ Heat Treated Stainless Steel produces exceptional integrity, consistent performance and precise archforms.

- Optimized manufacturing process allows you to add multiple step bends without breaking the wire.

- Proprietary polishing process creates smoother wires with enhanced sliding mechanics.

TitanMoly™ Titanium Molybdenum

Possibly the perfect archwire, G&H TitanMoly™ offers incredible versatility and performance. Offering the flexibility and recovery of NiTi and the strength and force of stainless steel, this could be the only wire you use on a patient from start to finish.

- Add step bends at any time, even early in treatment.

- Proprietary polishing process creates a smoother surface finish and improved sliding mechanics.

- Nickel-free for sensitive patients.

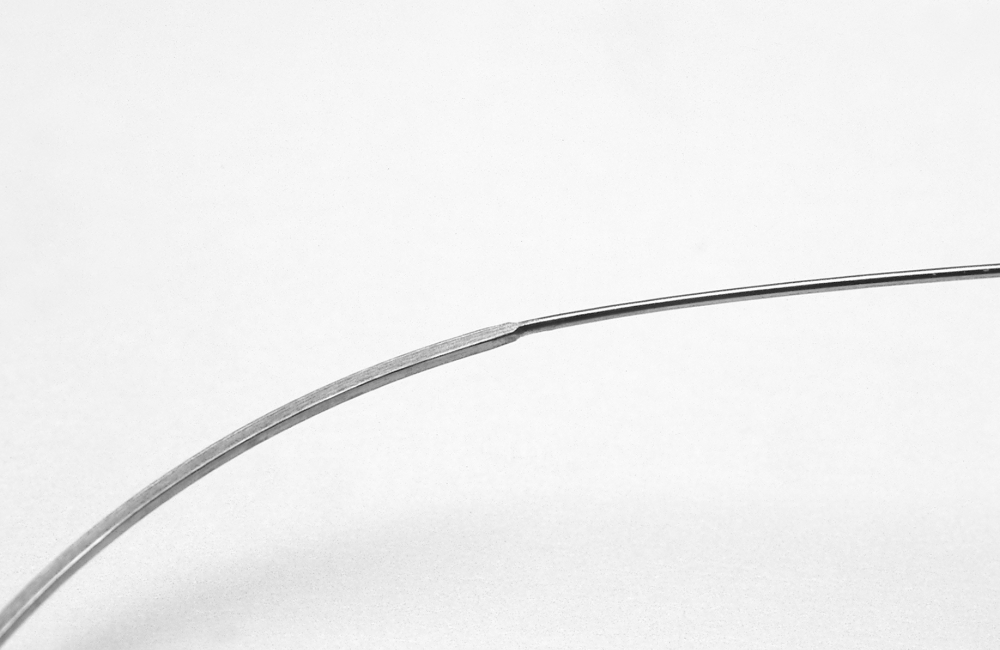

Colboloy™ Blue Nickel Cobalt

This unique alloy allows for intricate bending and can be heat treated after formation to increase tensile strength and resiliency. G&H Colboloy™ Blue Nickel Cobalt archwire is precisely engineered and goes through stringent testing to ensure quality and performance.

- Hone in on your desired softness/hardness for specific cases.

- Easily create bends to more precisely produce the force and movement you need.

A.J. Wilcock® Australian Wire

Imported exclusively to North America through G&H Orthodontics, A.J. Wilcock Australian Wire has earned its reputation as the finest stainless steel of its kind. These world-renowned wires offer superior hardness and strength for applications where exceptional resilience is needed.